HIGH VOLTAGES CAPACITOR

"ALL-FILM" Medium voltage CAPACITORS

Medium voltage capacitors are composed of elementary or partial capacitances, generally

connected in several series-parallel groups, providing the required electrical characteristics for the unit.

- The nominal voltage of a capacitor depends on the number of groups in series

- The nominal power of a capacitor depends on the number of partial capacitances in parallel per group

Each elementary capacitance is made of two sheets

of aluminium foil forming the reinforcements or the

electrodes and special high quality polypropylene film

which is rough to assist impregnation, forming part of

the insulation.

This wired capacitance assembly, referred to as the"active part", is positioned in a stainless steel case,

which has insulated porcelain terminals or bushings at

the top for connecting the device.

After the "active part" has been dried and treated, is

impregnated under vacuum with a liquid dielectric of

the following type :

- Non-chlorinated

- Non-toxic

- Biodegradable

With the polypropylene film, this liquid dielectric,

which has a remarkably high chemical stability,

a high gas absorption capacity and a high partial

discharge extinction capacity (discharges for which

the flash point is approximately 150°C), ensures total

insulation between electrodes.

This "all-film" capacitor

technology has the following main characteristics :

- Excellent resistance to strong electrical fields

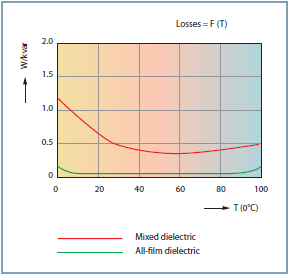

- Very low power losses, leading to considerable savings for high power capacitor banks

Variation of the W/kVA r losses as a function of the temperature |

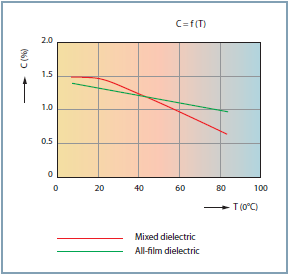

Variation of the capacitance C (μF) as a function of the temperature |

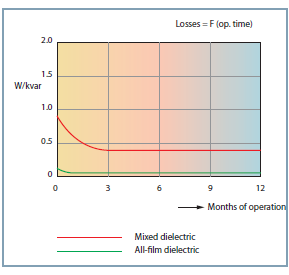

Variation of the W/kVA r losses as a function of the operating time |

|

|

|

In comparison with the previous generation of "mixed"

type dielectric (paper + film) capacitors, synthetic"all‑film" type dielectric capacitors have a much longer

service life, due to :

- Their excellent thermal stability related to very low

power losses, due to the removal of the paper

- The remarkable chemical stability of the liquid

dielectric, giving :

- A high partial discharge absorption capacity

- High dielectric resistance to transient

overcurrents and overvoltages

- A very low variation of capacitance as a function of

temperature

- Average loss factor :

- 0.15 W/kVAr at power-up

- 0.1 W/kVAr after 500 hours' operation

- Variation of the capacitance as a function of the

temperature :

- Internal discharge device :

- Internal discharge resistors reducing the residual

voltage to 75 V in 10 minutes after disconnection of

the supply

- Frequency : Standard: 50 Hz (60 Hz on request)

- Reference standards :

- French : C 54 102

- International :

- IEC 60 871.1 and 2 (supply capacitors)

- IEC 60 110 (capacitors for air or water cooled

induction furnaces)

- German : VDE 0560/4,

VDE 0560/9

- British : BS 1650

- Other standards on request

• Permissible overloads

- Current: 1.3 I nominal continuously

- Voltage (between terminals) :

- 1.1 U nominal, 12 hours in every 24 hours

- 1.15 U nominal, 30 minutes in every 24 hours

- 1.2 U nominal, 5 minutes in every 24 hours

- 1.3 U nominal, 1 minute in every 24 hours

• Standard insulation levels (phases/earth) for individual capacitors

• Individual tests

- Measurement of capacitance and losses

- Voltage test between terminals, i.e. :

- 2 U nominal, 10 s. AC voltage

- 4 U nominal, 10 s. DC voltage

- Voltage test between joined terminals and earth at industrial frequency

- Test of discharge device and seal-tightness of the

case.

Protection devices for "all-film" MV capacitors

There are four protection options for "all-film"

MV capacitors :

- Without internal fuses and external protection by

unbalance monitoring

- With internal fuses and external protection by

unbalance monitoring

- Without pressure monitoring device and external

protection by HRC fuses

- With pressure monitoring device and external

protection by HRC fuses

The choice between these four options is dependent on

the following criteria :

- Electrical characteristics of the capacitor (power,

voltage, connection)

- Customer's requirements concerning the sensitivity

of the protection device

The following table gives the possible type of protection for the capacitor and its advantages, according to the above criteria.

Installation conditions for "all-film" MV capacitors

Temperature class

• Standard: - 25/+ 45°C :

- 45°C average over 1 hour

- 40°C average over 24 hours

- 30°C average over 1 year

Protection against corrosion

- Installation possible: indoor or outdoor

- Stainless steel case, with one coat of primer and several top coats (RAL 7033)

Compatibility with the environment

- "All-film" capacitors are impregnated with a

(PCB‑free) biodegradable liquid dielectric. Their

installation does not require any particular precautions

with regard to the environment.

Dimensions and weights of "all-film" MV capacitors