TC CONTACTOR

CAPACITOR DUTY CONTACTOR

In Low Voltage installations, when a Capacitor is switched ‘ON’, it results in resonant circuit damped to a greater degree. In addition to the rated current, over current of high amplitude (>180 In) and high frequencies (3~15 KHz) occur during transit period (1 to 2 ms). The resultant high in-rush current peaks, caused due to capacitor switching, depends upon following factors :

- Network inductances

- Transformer power and short circuit voltage

- Type of power factor correction : fixed or automatic

- Harmonics presence in the system

The in-rush current of such high magnitudes is undesirable and it is likely to weld main poles of any standard contactor. Therefore, contactor for capacitor bank switching must be designed to with stand :

- Permanent current that can reach 1.5 time the nominal current of capacitor bank

- Short but high peak current on pole closing

Hence, selection of capacitor duty switching device requires careful product selection. It is always recommended to use dedicated Capacitor Duty Switching Contactor for switching Capacitor bank, which optimizes the switchgear cost & enhances the equipment life.

Operating Principal

Capacitor contactor are specially designed to meet stringent requirements of capacitor switching as deliberated above. These contactors ar efitted with front-mounted block of 3 early make auxiliary contact inseries with quick discharge damping six-resistors- 2 perphase to limit peak current to value within contactor making capacity such that normal rated capacitor current is carried by main contacts which, after closing, effectively short out the resistors.

Product Range

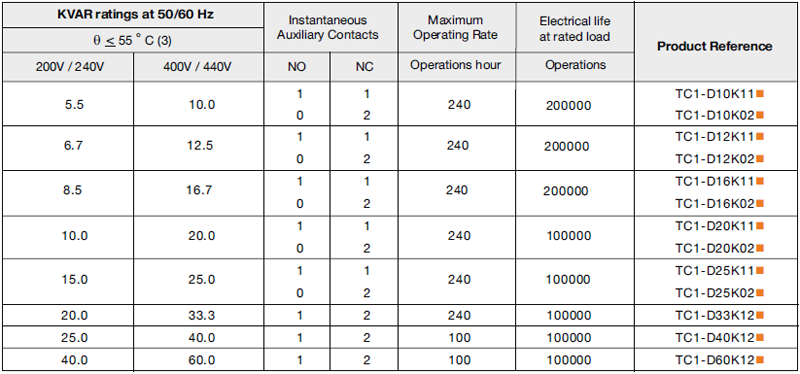

- Eight Ratings : 10 kVAR ~ 60 kVAR 3 P, 415 VAC, 50/60Hz

- Conforms to IEC 60947-4-1 and IS1 3947-4-1 AC - 6 but ilization category

Features and Benefits

- Excellent damping of In-rush Current

- Reduced watt loss during ‘ON’ condition, saves energy

- Capacitor Bank Switching in parallel without de-rating

- Enhanced equipment life

- Low main tenance & down-time

- Power quality improvement

- Optimized solution cost

Specification